First, I wanted it to suit my needs and fit my phone exactly.

Second, I like to make stuff - so why pass up the opportunity to invent something new!?

Design Requirements

The basic requirement of this design was to firmly hold my phone upright without tipping over. But there were other things I had to consider in this design. Here's the full list:

- Hold phone upright (portrait) without tipping and with firmness that let me tap the screen.

- Hold phone in sideways (landscape) too. (hopeful on this one)

- Have a slight angle so it is easy to see on my desk.

- Nothing should block ANY of the screen.

- Simple & Fast to print - no supports, flat bottom surface to grip print bed, minimal mass.

- Able to hold phones approximately the size of my Nexus 6P with or without a case.

Things I decided not to worry about for this first design included a way to dock the phone on the charging cable or making the stand portable to fit in my pocket. As with any product, sometimes it's just as important to pick things you're NOT trying to solve as it is to pick those problems you ARE trying to solve.

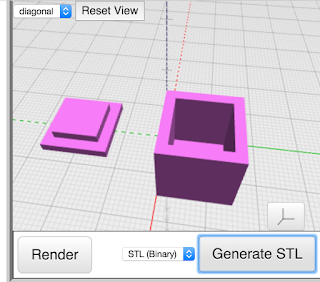

The 3D Model

This one was not as simple as it looks. The requirements I had to be simple and low mass made it more of a challenge - otherwise, I could have simply used a big block (as I've seen in many other phone holders).

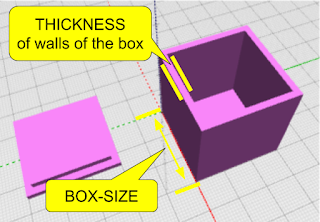

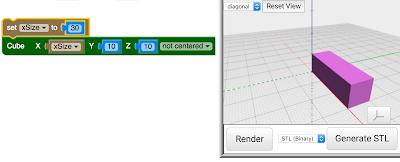

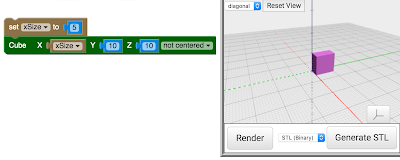

I started with a block. I imagined the shape I wanted to be more like a wedge, holding the phone on the front, then angled back to the bottom surface.

To get the right shape of the front which would hold the phone, I created a 3D Model of my phone - not to be printed, but to be used as a shape to SUBTRACT from the wedge block to leave behind a perfectly shaped area to hold my phone. I then subtracted a large chunk of the block from the angled front for the area where the phone screen would be seen, leaving about 5mm on each side, about 3mm thick, to hold the phone in place by the edges.

To get the right shape of the front which would hold the phone, I created a 3D Model of my phone - not to be printed, but to be used as a shape to SUBTRACT from the wedge block to leave behind a perfectly shaped area to hold my phone. I then subtracted a large chunk of the block from the angled front for the area where the phone screen would be seen, leaving about 5mm on each side, about 3mm thick, to hold the phone in place by the edges.

Now, as with any subtraction operation like this, the fit would be too tight if I just printed it as is - so I pushed out the insides of the phone holding area by 0.5mm on each side, and the back by 1mm.

To reduce the mass of the wedge, I wanted to cut out a large part of the back - so I made a copy of the whole wedge, and scaled it down to be a subtraction shape. I made it smaller by about 5-8 mm on each side and the part behind the phone, and then subtracted it from the back of the wedge - leaving the back of the wedge with no material at all.

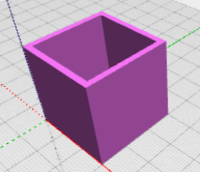

The shape I got was pretty much what I imagined! I finished it up by softening all the edges with a "Filet" operation (in Autodesk 123D) and gave it a first print.

I measured the space for my phone with the case - so the space for the phone was actually bigger than the phone itself by a few mm on each side.

The first print actually worked well with the phone that had the case on it, as it was a tight enough fit to really hold the phone firmly. But when I removed the case from the phone, the fit was so loose, that the weight of the phone leaning against the back of the stand let the stand slide up the phone and pop off the top.

I needed to create some friction or pressure for phones without cases - I had no intention of making a new stand for every phone or for phones without cases.

I decided to try a flexible "bow" in the back - just a very thin (1mm) printed flat strap, which would be stuck into two small holes into the inside of the phone holding area - creating pressure against the back of the phone and holding in in place when there was no case on it.

This worked!

I started with a block. I imagined the shape I wanted to be more like a wedge, holding the phone on the front, then angled back to the bottom surface.

To get the right shape of the front which would hold the phone, I created a 3D Model of my phone - not to be printed, but to be used as a shape to SUBTRACT from the wedge block to leave behind a perfectly shaped area to hold my phone. I then subtracted a large chunk of the block from the angled front for the area where the phone screen would be seen, leaving about 5mm on each side, about 3mm thick, to hold the phone in place by the edges.

To get the right shape of the front which would hold the phone, I created a 3D Model of my phone - not to be printed, but to be used as a shape to SUBTRACT from the wedge block to leave behind a perfectly shaped area to hold my phone. I then subtracted a large chunk of the block from the angled front for the area where the phone screen would be seen, leaving about 5mm on each side, about 3mm thick, to hold the phone in place by the edges.Now, as with any subtraction operation like this, the fit would be too tight if I just printed it as is - so I pushed out the insides of the phone holding area by 0.5mm on each side, and the back by 1mm.

|

| Landscape works too! |

The shape I got was pretty much what I imagined! I finished it up by softening all the edges with a "Filet" operation (in Autodesk 123D) and gave it a first print.

Making it more useful

|

| Landscape is great for video watching |

I measured the space for my phone with the case - so the space for the phone was actually bigger than the phone itself by a few mm on each side.

The first print actually worked well with the phone that had the case on it, as it was a tight enough fit to really hold the phone firmly. But when I removed the case from the phone, the fit was so loose, that the weight of the phone leaning against the back of the stand let the stand slide up the phone and pop off the top.

I needed to create some friction or pressure for phones without cases - I had no intention of making a new stand for every phone or for phones without cases.

I decided to try a flexible "bow" in the back - just a very thin (1mm) printed flat strap, which would be stuck into two small holes into the inside of the phone holding area - creating pressure against the back of the phone and holding in in place when there was no case on it.

This worked!

The Model is published HERE.