Quick Summary

After using the Glowforge Plus (middle model) for a few weeks, I'm extremely positive and 100% satisfied with it. I've worked with acrylic, wood and cardboard - and mainly with custom designed projects so far, and I've had no issues and have a very positive experience with the company and the community forum. (Note: if you're thinking of buying one, this link will give you a $100 - $500 discount and will give us referral points for craft materials so we can do more project posts here! ;)I waited too long to buy my first 3D Printer - probably 2 years from the time I considered it. Once I dove in, I regretted that wait and wished I started earlier. Recently I started getting the same feeling about trying Laser Cutting - but this time was different. I saw laser cutters before, and they were simply too high maintenance and "shop ready" rather than "home ready". So I waited, hoping that I could eventually see a more home ready laser cutter at some point. Then, Glowforge happened - and while this kickstarter-born phenomenon took way longer to launch than I had hoped, it finally did start shipping this summer, and I committed.

Pricing

While the Glowforge was not cheap (gulp - $2,495 for the entry level, $3,995 for the middle model and $5,995 for the pro level as of this writing - I got the middle model), it met all my other criteria and was clearly angled to the "Easy enough for anyone" category. That promise has been the most positive aspect of the product.

While the Glowforge was not cheap (gulp - $2,495 for the entry level, $3,995 for the middle model and $5,995 for the pro level as of this writing - I got the middle model), it met all my other criteria and was clearly angled to the "Easy enough for anyone" category. That promise has been the most positive aspect of the product.Un-boxing

The Glowforge was packaged and shipped with high attention to detail and safety - but easy to unpack, even with it's large size. I was pleasantly surprised that it also came with a huge box of various sample materials - and following the simple directions online, I was set up and printing/cutting within an hour from delivery! Set up of the hardware and the software was REALLY easy. Since all the print/cut prep is done on the software and the device itself only has one button!

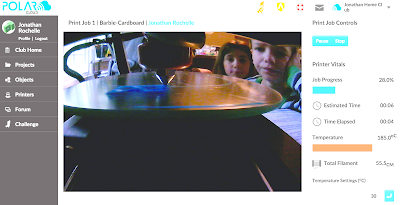

The Glowforge App is available on the web - which is HUGE... That means I can get to it on a chromebook or any other device - and I am able to access all my designs, interact with the printer, even see the print/cut bed through the built-in camera. It is incredibly easy to use - to align a design - even resize, move and rotate it - so that it prints on the material that is in the printer at the time. This really helps to maximize usage of the material you have (by using the un-used sections of partially used material). There is also an iOS app, but I haven't tried that...

To get a design into the Glowforge app, I can upload it (SVG format is what I use) or even put a printed or even hand-drawn version of the design in the printer, scan it, and then print/cut it on the wood/acrylic/whatever material! It's truly magical to let my daughter draw something - scan it in the printer - and then cut that design onto the material!

I also printed one of their sample boxes which had intricate connectors that worked incredibly well.

I've included images (and one quick video) of some early projects I made - puzzle, custom-designed box (to store the puzzle) and the pre-designed box from the Glowforge library.

Watch this space for posts on the Glowforge projects we pursue here at MkrClub - I've already got a few really fun projects done and waiting to be posted. And - If you found this review helpful - feel free to use THIS LINK to buy the Glowforge - as it will give you a great discount and give me referral points for buying materials for projects :)

Setup & Venting

The main setup challenge for some buyers will be the venting - make sure you can put this near a window or external vent. I'm lucky to have a window nearby and I use the INCLUDED dryer-vent-style hose to vent the exhaust through a window rig. Glowforge is apparently creating a filter system - but that's not available yet - so venting for now is a must. If you don't have a way to vent the exhaust from cutting, don't buy any laser cutter. The exhaust fan in the Glowforge is powerful, and it does a great job of pushing the cutting exhaust through the vent.The App (in your browser!)

|

| The GlowForge App home - where my designs live |

To get a design into the Glowforge app, I can upload it (SVG format is what I use) or even put a printed or even hand-drawn version of the design in the printer, scan it, and then print/cut it on the wood/acrylic/whatever material! It's truly magical to let my daughter draw something - scan it in the printer - and then cut that design onto the material!

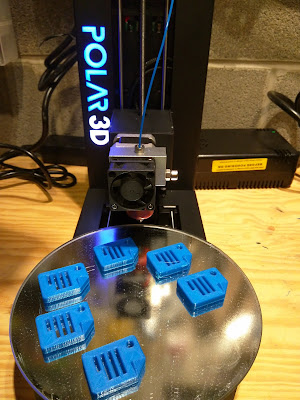

First Projects

One of my first custom-designs was a tiny jigsaw puzzle. I used a simple drawing product on the ipad (vectornator) and exported the SVG. pulled that into the Glowforge app, and in 1 minute, 48 seconds, the puzzle was done - on draftboard (chipboard-like wood from Glowforge sample pack). It came out AMAZING! I've experimented with making photo puzzles, and almost have a winner ;) - just have to play more with protecting the photo during cutting (look for that post coming soon!).I also printed one of their sample boxes which had intricate connectors that worked incredibly well.

I've included images (and one quick video) of some early projects I made - puzzle, custom-designed box (to store the puzzle) and the pre-designed box from the Glowforge library.

Glowforge Community & Library

The online resources at Glowforge.com are incredibly valuable. The community is very active and responsive - so any questions I had were answered within a day by experienced owners and the company itself. I've been finding answers there for practically every topic - including cutting non-standard materials, venting ideas, design apps, etc.There is also a library of designs - some free, some for pay, which is definitely another great resource, particularly for those who are not inclined to start from scratch.Summary

This was a tough purchase decision - practically the cost of a small family vacation - but the Glowforge has exceeded my high expectations in every way! If you're a crafter, who makes a business making things, the Glowforge seems like a must-have. If you're a #Maker, 3D-printing enthusiast or a just a hobbyist and just want to tinker with Laser-cutting, you should seriously consider the Glowforge.Watch this space for posts on the Glowforge projects we pursue here at MkrClub - I've already got a few really fun projects done and waiting to be posted. And - If you found this review helpful - feel free to use THIS LINK to buy the Glowforge - as it will give you a great discount and give me referral points for buying materials for projects :)